Protect Your Eyes.

Trust Only Verified Eclipse

Glasses.

Millions of eclipse viewers unknowingly risk permanent eye damage using counterfeit glasses. We are the definitive resource for ISO 12312-2 compliance—providing independent verification, rigorous testing standards, and a trusted list of manufacturers who meet real safety requirements.

What is ISO 12312-2?

ISO 12312-2:2015 is the international standard that defines the safety requirements for filters used in direct observation of the Sun—including eclipse glasses and handheld solar viewers.

Adopted in 2015 by the International Organization for Standardization (ISO), this standard establishes precise criteria for transmittance, material quality, and labeling that genuine solar viewers must meet to protect your eyes.

Important: No product is "ISO certified" by ISO itself. Compliance must be verified by accredited testing laboratories. We require manufacturers to provide proof of testing from labs accredited under the ILAC Mutual Recognition Arrangement.

Full Standard DetailsWhat Makes Eclipse Glasses Safe?

ISO 12312-2 specifies rigorous requirements across multiple categories. All criteria must be met—failure in any area means the product is not safe.

Light Transmittance

Filters must block sufficient visible, UV, and infrared light to protect the retina while allowing a comfortable view of the Sun.

Material Quality

Filters must be free from defects that impair vision or safety—no bubbles, scratches, pinholes, or surface irregularities that could allow light leakage.

Labeling & Traceability

Products must display manufacturer information, usage instructions, safety warnings, and proper care guidelines—enabling full traceability.

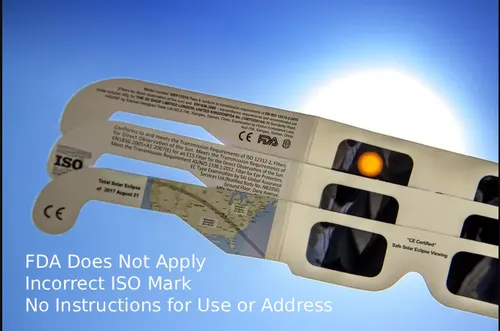

The Danger of Fake "ISO Certified" Glasses

Before every major eclipse, counterfeiters flood online marketplaces with cheap glasses that claim ISO 12312-2 certification. Many copy legitimate certificates or simply print "ISO" on unsafe products. These fakes can cause permanent retinal damage in seconds.

- Prices that seem too good to be true (under $1 per pair wholesale)

- Missing or vague manufacturer information

- Certificates with mismatched product names or dates

- Claims of "ISO certified" or "ISO approved" (ISO does not certify products)

- No verifiable testing laboratory or Notified Body information

Full Compliance. No Exceptions.

Some organizations have taken it upon themselves to decide that the ISO 12312-2 standard is "too strict" and have listed products that only meet transmission requirements while failing labeling, packaging, or uniformity requirements. We reject this approach entirely.

ISO 12312-2 is a complete standard. Every requirement exists for a reason—developed by international experts who understand that eye safety involves more than just blocking light. A product either meets ALL requirements of the standard, or it does not meet the standard. Period.

How We Verify Manufacturers

Unlike organizations that accept any submitted certificate, we conduct rigorous independent verification. Only manufacturers who pass every step appear on our list.

Application

Manufacturer submits product samples and all certification documentation for review.

Lab Verification

We verify testing lab accreditation under ILAC MRA for ISO 12312-2 specifically.

Product Testing

Independent testing confirms actual products meet all transmittance and quality requirements.

Ongoing Monitoring

Approved manufacturers are subject to periodic re-verification and random sample testing.

Get Your Products Verified

Join the trusted list of ISO 12312-2 compliant manufacturers. Verified products receive prominent placement before major eclipse events.

Learn More

Understanding the Standard

Complete breakdown of ISO 12312-2 requirements, testing methods, and what compliance actually means.

Read More →Verify Your Glasses

Step-by-step guide to checking if your eclipse glasses are genuine and safe to use.

Read More →EU/UK CE Marking

Additional requirements for products sold in Europe under EN ISO 12312-2:2022.

Read More →